Functional safety

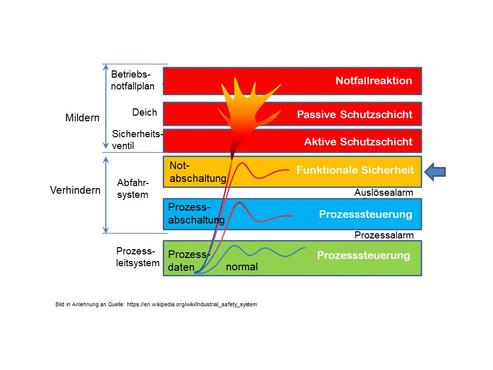

Functional safety is the final preventive measure for avoiding accidents in an emergency situation. It is achieved through technical safety functions that are implemented using electrical, electronic and/or programmable electronic systems. Functional safety aims to reduce the probability of hazardous situations occurring, thereby reducing the risks to humans and the environment to a justifiable level.

Contact

Robert Hannemann

Head of Conformity Services

Functional safety

Functional safety is the final preventive measure for avoiding accidents in an emergency situation. It is achieved through technical safety functions that are implemented using electrical, electronic and/or programmable electronic systems. Functional safety aims to reduce the probability of hazardous situations occurring, thereby reducing the risks to humans and the environment to a justifiable level.

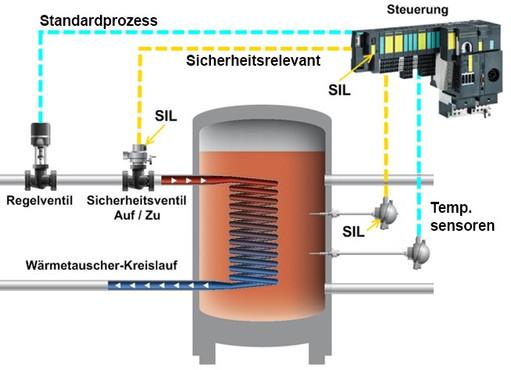

The safety integrity level (SIL) is used to assess the reliability of safety functions.

The SIL is defined based on the risk of a hazardous situation occurring. It defines requirements for safety functions that are intended to bring the risk to an acceptable level.

IEC 61508 defines the essentials of functional safety. For many industries, the requirements have been carried over into industry-specific standards.

For example:

- IEC 61511 – Functional safety – Safety instrumented systems for the process industry sector

- EN 50156 – Electrical equipment for furnaces and ancillary equipment

These standards apply from a system’s planning and design to its operation and maintenance, extending to its dismantling and decommissioning.

Benefits and services

How you will benefit

- Your management system will comply with the requirements of IEC 61508/IEC 61511

- Your system will be made safe in line with the state of the art

- The operation and maintenance of your systems will meet functional safety requirements

- Independent and neutral

Services offered

- Consulting on the introduction of management systems for functional safety

- Moderation and documentation of risk analyses with SIL classification

- Consulting/review of safety requirements specifications

- Consulting on the choice of components for SIL functions

- Preparing/reviewing SIL evidence

- Inspection/acceptance of safety functions on site

- Preparing/reviewing maintenance concepts

«Functional safety is where electrical engineering meets mechanical engineering. And thanks to digitalization, it's not just the controls that are becoming smarter, but also the possibilities for monitoring and influencing them.»

Oliver von Trzebiatowski, CTO of the SVTI Group